Efficient filtration is the backbone of countless industries, from food and beverage production to chemical processing and water treatment. A well-designed filtration system ensures product quality, minimizes waste, and boosts operational efficiency. The humble yet essential filter press cloth is at the heart of these systems.

This blog explores the critical role of filter cloths, exploring their applications, key materials, and benefits, and how recent advancements are redefining efficiency. Whether in oil and gas or managing environmental projects, understanding filter press cloth technology can significantly enhance your industrial processes.

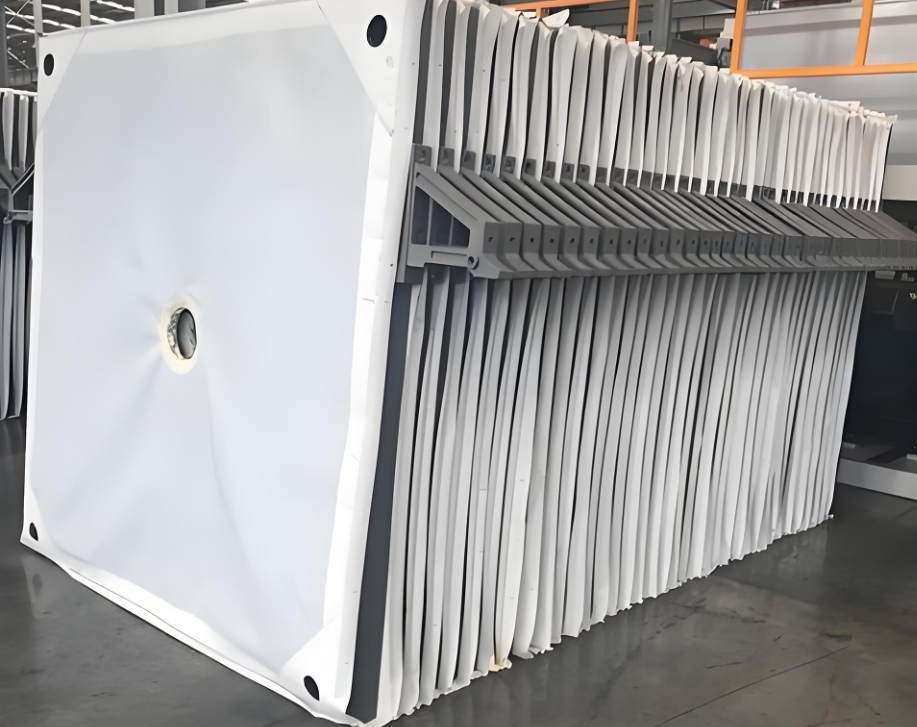

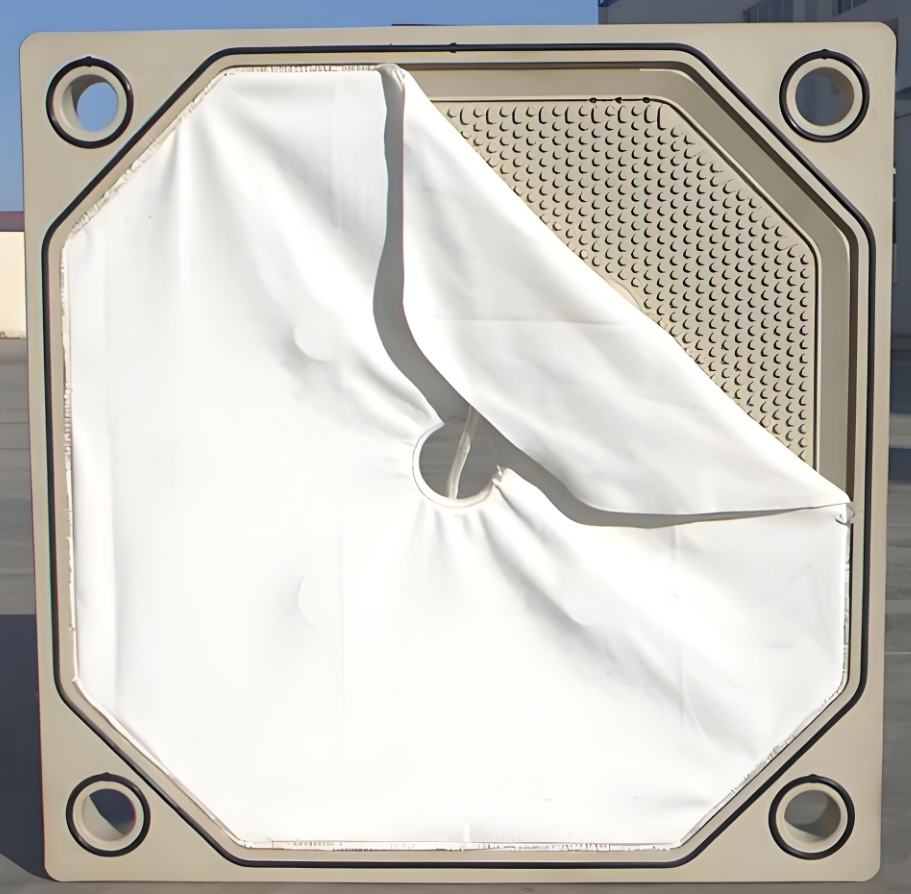

Filter Cloth for Filter Press: Understanding the Basics

Filter press cloths are essential in industrial filtration systems. They separate solids from liquids by capturing solid particles while allowing liquids to flow through, ensuring product quality and operational efficiency.

Materials Used

Filter press cloths are made from various materials, each tailored for specific applications and environments. Common options include:

- Polyester Filter Cloths: Known for durability and high adaptability, ideal for general-purpose filtration.

- Polypropylene Filter Cloths: Excellent chemical resistance, perfect for acidic and alkaline solutions.

- Nylon Filter Cloths: High tensile strength and temperature tolerance, used in demanding conditions.

Importance in Filtration

These clothes are vital in maintaining filtration consistency. Whether separating contaminants from water in treatment plants or ensuring the purity of pharmaceuticals, the right filter press cloth improves output and reduces downtime.

Choosing the Right Filter Cloth Material

Appropriate filter cloth material is essential for meeting your unique industrial requirements.

Factors to Consider

- Filtrate Properties: The nature of the liquid (viscosity, chemical composition) determines the suitable material.

- Temperature and Environment: High-temperature processes require resilient materials like nylon or specialty blends.

- Filter Cake Characteristics: The nature of solids retained, such as abrasiveness or stickiness, impacts material choice.

Material Selection

Consider this example:

- Polypropylene performs remarkably in chemical industries, handling corrosive solutions without degrading.

- Polyester thrives in abrasive settings due to its durability, making it a popular choice in cement and construction.

- Nylon, with its superior temperature and pressure tolerance, is invaluable in oil and gas operations.

Success stories from industries like pharmaceuticals highlight how selecting the right cloth can improve product purity and operational longevity.

Industrial Filtration Solutions with Filter Press Cloths

Filter press cloths are versatile and serve numerous industries. Their ability to improve production efficiency while reducing costs makes them indispensable across sectors.

Applications Overview

- Mining and Ore Processing: Essential for filtering metals and minerals from ore concentrates.

- Chemical Processing: Delivers consistent filtration when handling corrosive substances.

- Wastewater Treatment: Removes suspended solids, ensuring compliance with environmental standards.

Benefits of Filter Press Cloths

- Efficiency: Advanced cloth materials and weaves ensure faster filtration cycles.

- Cost Reduction: Lower energy consumption and maintenance costs.

- Enhanced Product Quality: Superior filtration means fewer impurities in the end product.

Real-World Success

When a water treatment facility adopted polyester filter cloths from TefloFilter, filtration cycles improved by 30%, leading to significant cost savings. Explore TefloFilter’s product range for more solutions like this.

Filter Press Cloth for Ore Concentrate and Tailings Filtration

Mining presents unique filtration challenges, making the selection of filter press cloths critical.

Challenges in Ore Concentrate Filtration

Handling slurry with high solid contents can be taxing. Polyester and polypropylene cloths effectively manage the varying pH levels and abrasive nature of ore concentrate filtration.

Tailings Filtration Solutions

Tailings management is a key environmental priority. Non-woven filter press cloths provide efficient solid-liquid separation, increasing water recovery rates and reducing waste.

Best Practices

- Use anti-static coatings to avoid particle adhesion.

- Regularly inspect filter cloths to ensure optimal performance and avoid wear and tear.

Maximizing Efficiency with Advanced Filter Press Cloths

With recent advancements in materials and designs, filter press cloths are more efficient than ever.

Technological Advancements

- Improved Fabrics: High-tensile, woven polyesters, and multi-layer weaves provide unmatched durability.

- Surface Coatings: Hydrophobic or oleophobic coatings enhance filtration by repelling unwanted contaminants.

- Smart Integration: RFID tags for easy monitoring and inventory management.

Efficiency Tips

- Regular Cleaning: Keep your filter cloths free of clogs to maintain peak performance.

- Custom Fittings: Ensure your clothes are tailored to your filter press dimensions.

- Routine Maintenance: Periodic checks reduce downtime and extend the life of your clothes.

Cost Savings and Environmental Benefits

Efficient filter cloths lower operating costs by reducing energy consumption. They also greatly contribute to sustainability, cutting waste and improving water recovery processes.

Driving Industrial Processes Forward with TefloFilter

At the forefront of filtration technology, TefloFilter provides solutions tailored for diverse industries. Focusing on innovation and quality, its polyester, polypropylene, and nylon filter cloths set the benchmark for efficiency and reliability.

Why Choose TefloFilter?

- Industry Expertise with 25+ years of filtration solutions.

- Wide Range of Materials to meet specific industrial needs.

- Enhanced Filtration Efficiency backed by innovative designs.

Take your industrial filtration system to the next level. Consult the team at TefloFilter to find the perfect filter cloth solution for your business.

The Future of Filtration Efficiency

The evolution of filter press cloth technology is shaping industries by improving efficiency and productivity. The future holds tremendous potential for further innovation, from advanced materials to sustainable practices.

Don’t settle for outdated filtration processes. Upgrade to advanced filter press cloths and experience the difference today.