The Evolution of Printed Circuit Board Assembly (PCBA)

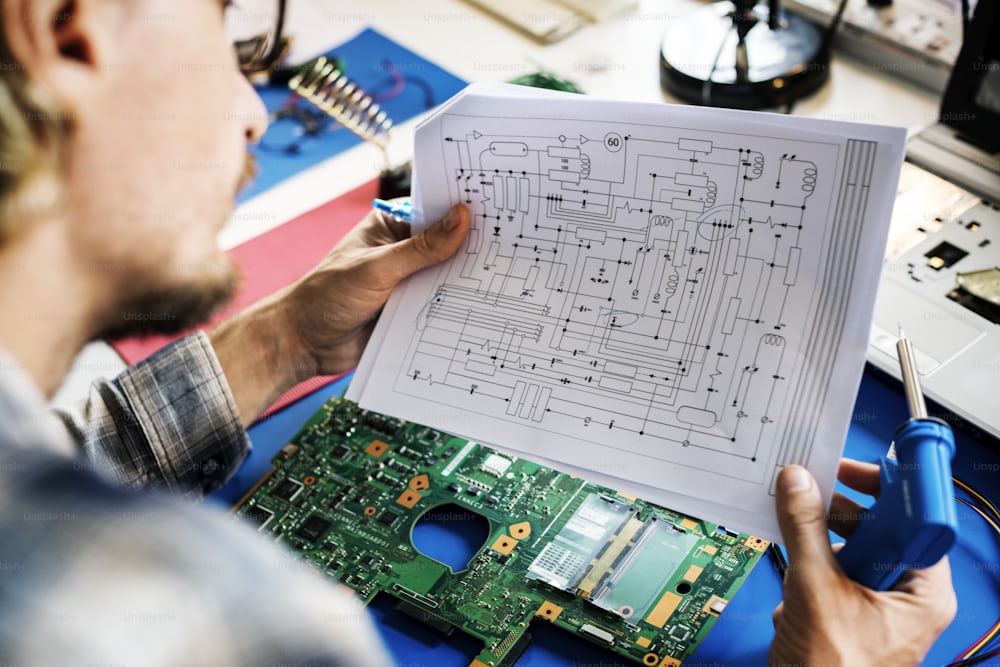

The demand for high-performance electronics continues to grow, driving rapid advancements in printed circuit board assembly (PCBA). As technology evolves, manufacturers integrate automation, artificial intelligence (AI), and innovative materials to improve efficiency, reduce costs, and enhance circuit board functionality.

For printed circuit board manufacturers, staying ahead of these trends is critical to maintaining competitive advantages and meeting the increasing demand for high-quality, high-density PCBs. This article explores the key innovations shaping the future of PCBA and how they are redefining circuit board production.

The Shift Towards Smart Manufacturing in PCBA

As electronic components become more complex, the industry is adopting innovative manufacturing technologies to enhance production efficiency and reduce human error. Smart factories leverage automation, machine learning, and real-time data monitoring to improve yield rates and streamline workflows.

- AI-Driven Quality Control

- Automated Optical Inspection (AOI): AI-powered cameras detect defects in real time, ensuring precise soldering and alignment.

- Predictive Maintenance: AI algorithms anticipate machine failures before they occur, minimizing downtime and production losses.

- Robotics in PCB Assembly

- Pick-and-Place Machines: Advanced robotic arms place thousands of components per hour with micron-level accuracy.

- Automated Soldering Systems: These improve consistency in solder joints, reducing manual rework.

- oT-Connected Production Lines

- Real-Time Monitoring: Sensors track temperature, humidity, and process variables, ensuring consistent production quality.

- Remote Diagnostics: Engineers can analyze performance and troubleshoot issues from anywhere.

By integrating AI, robotics, and IoT, printed circuit board manufacturers significantly improve production speed and reduce manufacturing defects.

The Role of Advanced Materials in PCBA Innovation

Material science plays a crucial role in enhancing printed circuit board assembly performance. New materials improve thermal conductivity, durability, and flexibility, allowing PCBs to support more advanced applications.

- High-Density Interconnect (HDI) PCBs

HDI PCBs use advanced materials to support miniaturization in smartphones and medical implants. Benefits include:

- Increased Layer Density: More functionality in a smaller footprint.

- Improved Signal Integrity: Reduced electromagnetic interference (EMI).

- Flexible and Rigid-Flex PCBs

Flexible PCBs allow for innovative product designs, such as foldable smartphones and wearable devices. Their advantages include:

- Enhanced Durability: Withstands bending and vibration.

- Lightweight Construction: Reduces overall device weight.

- Thermal Management Materials

High-power electronics require better heat dissipation to prevent failures. Innovations include:

- Metal-Core PCBs (MCPCBs): Used in LED lighting and automotive applications.

- Graphene-Based Substrates: Providing ultra-high thermal conductivity.

Manufacturers improve PCB reliability, longevity, and performance by adopting these materials, making them ideal for next-generation technology.

Automation and Industry 4.0 in PCB Manufacturing

The rise of Industry 4.0 is revolutionizing printed circuit board assembly through interconnected systems and automated decision-making.

- Digital Twin Technology

A digital twin is a virtual model of a PCB production line that allows manufacturers to:

- Simulate process optimizations before implementation.

- Predict failures and adjust workflows in real-time.

- Improve supply chain visibility and efficiency.

- 3D Printing for Rapid Prototyping

Traditional PCB prototyping can take weeks, but 3D printing accelerates the process by:

- Reducing the need for multiple design iterations.

- Allowing faster validation of new PCB layouts.

- Supporting complex, non-traditional circuit board shapes.

- Blockchain for Secure Supply Chains

To prevent counterfeit components, blockchain technology is being used to:

- Provide tamper-proof records of PCB components.

- Authenticate supplier transactions.

- Improve transparency in global PCB distribution networks.

By adopting Industry 4.0 technologies, printed circuit board manufacturers can enhance efficiency, accuracy, and security across their supply chains.

Sustainability and Eco-Friendly PCB Manufacturing

Environmental concerns are shaping the future of printed circuit board assembly, with manufacturers focusing on reducing waste, energy consumption, and hazardous materials.

- Lead-Free Soldering

- Regulations such as RoHS (Restriction of Hazardous Substances) mandate the reduction of lead and other toxic metals in PCBs.

- Lead-free alloys improve environmental safety while maintaining performance.

- Biodegradable PCBs

- Researchers are developing PCBs using biodegradable substrates to minimize e-waste.

- Alternative materials like organic polymers are being tested for eco-friendly circuit production.

- Energy-Efficient PCB Fabrication

- Factories are adopting low-energy laser etching to reduce carbon footprints.

- Renewable energy sources, such as solar-powered PCB plants, are being integrated into production facilities.

Sustainability efforts will continue to drive innovation in the PCB industry, ensuring a greener future for electronics manufacturing.

The Future of PCBA and Its Impact on Global Electronics

The evolution of printed circuit board assembly is reshaping industries from consumer electronics to aerospace and medical devices. Innovations in automation, AI-driven manufacturing, advanced materials, and sustainability are setting new standards for efficiency and reliability.

Leading companies like Precision Electronics are at the forefront of these changes, leveraging cutting-edge technologies to stay ahead of the competition. As PCBA continues to evolve, manufacturers that embrace these advancements will unlock new opportunities for growth and innovation.

Keep an eye for more latest news & updates on Internet Chicks!